Emechaala

Emechaala

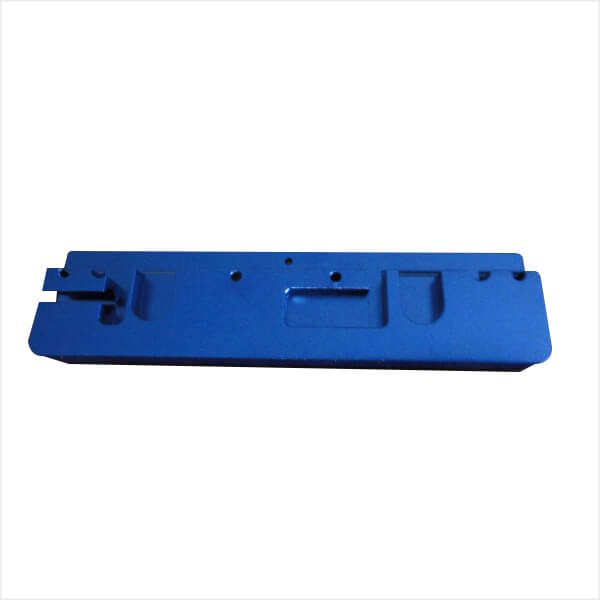

Ngwọta dị n'elu bụ elu nke ihe eji eme ihe iji mepụta oyi akwa na matriks nke n'ibu, anụ ahụ na kemịkalụ nke elu oyi akwa nke usoro.Ebumnuche nke ọgwụgwọ elu bụ izute nguzogide corrosion ngwaahịa, iyi nguzogide, ịchọ mma ma ọ bụ ihe ndị ọzọ chọrọ ọrụ pụrụ iche.Makametal machining akụkụ, ọzọ eji n'elu ọgwụgwọ ụzọ bụ n'ibu egweri, chemical ọgwụgwọ, elu okpomọkụ ọgwụgwọ, ịgba elu, n'elu ọgwụgwọ bụ n'elu nke workpiece ihicha, ihicha, deburring, ka mmanụ, descaling na na.

Kedu ihe bụ Metal Metal Finishing?

Ịmecha ọla bụ okwu zuru oke nke ejiri kọwaa usoro ịtụnye ụfọdụ ụdị mkpuchi ọla n'elu akụkụ ọla, nke a na-akpọkarị mkpụrụ.Ọ nwekwara ike ịgụnye mmejuputa usoro maka ihicha, ihicha ma ọ bụ imezi elu elu.Metal agwụcha na-enwekarị electroplating, nke bụ usoro na-edebe metal ion n'elu a mkpụrụ site na ọkụ eletrik.N'ezie, a na-eji metal emecha na platining mee ihe mgbe ụfọdụ.Otú ọ dị, ụlọ ọrụ na-emecha ígwè na-agụnye usoro dịgasị iche iche, nke ọ bụla na-enye uru nke onye ọrụ ya.

Ịmecha metal metal nwere ike ịrụ ọtụtụ uru bara uru gụnyere:

● Ibelata mmetụta nke corrosion

● Na-eje ozi dị ka uwe mkpuchi iji kwalite nchikota agba

● Na-eme ka mkpụrụ osisi dị ike na ịba ụba na-eguzogide

● Ibelata mmetụta nke esemokwu

● Ịmalite ọdịdị akụkụ

● Ịbawanye solderability

● Ime ka elu igwe na-eduzi ọkụ eletrik

● Na-akwalite nguzogide kemịkalụ

● Nhicha, ihicha na iwepu ntụpọ dị n'elu

Ụzọ ọgwụgwọ elu

Mechanical usoro

Nchacha

Mpempe mkpịsị aka dị elu nwere ọsọ a na-agbanwe agbanwe n'otu n'otu maka polishing kacha nke workpiece.

Ịkụ ụra

Ultrasonic-enyere aka lapping na polishing usoro maka obere akụkụ.

Nchacha nke ime

Site na usoro pụrụ iche, enwere ike imeziwanye ihe dị n'ime elu nke ogologo, nkịtị na obere tubes.

Site na usoro ndị a, enwere ike nweta mma elu dị mma dabere na ihe mmalite.

Emecha nke ọma jijiji

The workpiece na-enịm ke akpa na egweri wiil.Ntugharị na-agbagharị agbagharị na-eme ka a na-ewepụ akụkụ na ebe ndị siri ike, si otú a na-eme ka mma dị elu.

Aja na iko pearl gbawara agbawa

Maka imegharị ihe, ime ihe ike, nhazigharị ma ọ bụ matting elu.Dabere na ihe achọrọ, mgbasa ozi ịgbawa ọkụ dị iche iche na ntọala ntọala ga-ekwe omume.

Usoro kemịkalụ

Electropolishing

Usoro

Electropolishing bụ usoro mwepụ electrochemical nwere isi iyi ike mpụga.N'ime ihe electrolyte emebere nke ọma na ihe ahụ, a na-ewepụ ihe ahụ n'ụzọ anodically na workpiece ka a rụzie ya.

Nke a pụtara na ọla workpiece na-etolite anode na cell electromechanical.Igwe ahụ na-ahọrọ ịgbaze n'elu ebe na-ekwekọghị ekwekọ n'ihi oke ọgba aghara.A na-eme mwepụ nke workpiece na-enweghị nchekasị.

Ngwa

Mbelata nke ịdị nhịahụ elu, mmụba nke nguzogide corrosion nke elu, okirikiri dị mma.

Enwere ike itinye electropolishing naanị na elu elu nke cannulas.

Oke akụkụ ahụ nwere oke na max.500 x 500 mm.